Contents - Index - Previous - Next

Estimate the ballistic coefficient from a physical description of the bullet

The best method of determining the ballistic coefficient of any projectile is to physically measure the amount of velocity reduction over a carefully measured distance. Since that is not always possible, some means other than an educated guess is needed to estimate a reasonably accurate ballistics and trajectory package.

The Ballistic Coefficient of Tangential Ogive jacketed bullets traveling at velocities above the speed of sound can be calculated to a reasonable degree of accuracy if careful measurements are made to determine the actual radius curve of the nose portion and the boat tail (if any) dimensions.

Most ballistic calculators require that the bullet be laid upon a chart of different profiles in order to find a curve that most closely matches the curve of the ogive of the bullet.

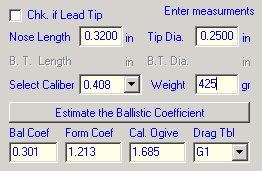

Close measurement of the distance from the start of the tangential ogival curve to the foremost part of the nose, the diameter of the tip and the diameter of the bullet can, by a mathematical formula, provide an exact value for the radius of the curve of the bullet ogive. This value, divided by the diameter of the bullet returns the "Caliber of the Ogive" From this value, the "Coefficient of Form" or "form factor" of the bullet may be calculated.

Applying a formula containing the measurements of the boat tail reduces the form factor in proportion to those measurements.

After the form factor is determined, it is divided into the weight of the bullet (in pounds) and the resulting value is divided by the square of the diameter of the bullet, thus calculating the ballistic coefficient of that bullet for the G1 Drag table.

This form factor may also be applied directly to the GL drag table. The G5 and G6 drag tables were compiled using projectiles of a smaller diameter and different nose conformations then the projectile used for the G1 table, so the form factor is increased in proportion to those differences to obtain the ballistic coefficients for bullets whose behavior more closely conforms to these bullet models.

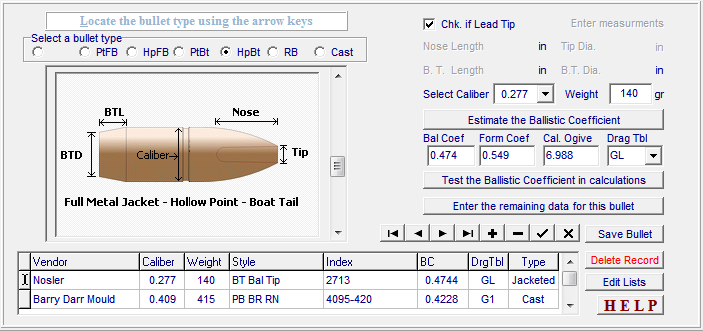

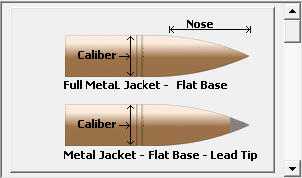

The software permits the selection of a graphic picture that most closely represents the type of bullet to be measured and the entry fields for the dimensions needed by the software for that particular configuration

Selection of the radio button, HpBt, opens fields that will allow the entry of tip diameter and boat tail measurement values and then sets the Drag Table entry field to G1.

![]()

Entering the measurements of the pictured Nosler boat tail Ballistic Tip bullet and clicking on the " Estimate the Ballistic Coefficient" button, returns a ballistic coefficient of 0.457. Nosler lists a ballistic coefficient in the G1 Drag Tables for this bullet of 0.456.

After the calculations are performed, the ballistic coefficient may be tested by clicking on the "Test the Ballistic Coefficient in Calculations" button, which will move the focus of the program to the Data EntryHlp_Precision_BallisticsxBallistics page where a starting velocity and range may be entered for a test calculation of the ballistic coefficient. Once these calculations are finished, selection of the Bullet Data page tab will return the focus to the Estimate Ballistic Coefficients page.

If subsequent test firings or the accumulation of hard data for this bullet indicate the need to adjust the estimated ballistic coefficient, it is a simple matter to retrieve the record from the Edit DatabaseHlp_Edit_Bullet page and change the value of the ballistic coefficient to a more realistic value.

Clicking on the Enter the remaining data for this bullet button will open the one line grid at the bottom of the page where the vital information pertaining to the bullet may be entered into a record and then stored in the Active bullet database by clicking on the Save a Bullet button.

If subsequent test firings, or the discovery of a known coefficient for this bullet, indicate the need to adjust the estimated ballistic coefficient, it is a simple matter to retrieve the record from the Edit DatabaseHlp_Edit_Bullet page and change that value.

When a bullet configuration is selected, the software enters the drag table type that should be best suited to that bullet. It is not necessary that the ballistic coefficient be calculated using this selection and the table designation may be changed before the calculations are made by choosing from the drop-down list in the Drag Tbl. entry field.

Possibly the most difficult part of the procedures is that of measuring the length of the nose, as it is quite hard to determine exactly where the main body ends and the curve of the radius starts. One method that works well is to set and lock a caliper tool to 0.001" less than the diameter of the nose of the bullet, then slide the calipers up the bullet nose, toward the bullet body, until the movement is stopped, then carefully mark that spot. It will be very close to the point where the bullet body becomes the start of the bullet nose.

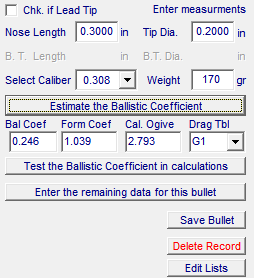

Calculation of ballistic coefficients for cast bullets requires a different algorithm than for jacketed bullets. When the radio button for Cast is selected and after the data

Selection of the HpFb radio button allows the entry of measurements taken from the Lyman cast bullet #311141 and returns the coefficient of 0.237 for the G1 drag table. Lyman, in the46th edition of their Reloading Handbook, list three separate ballistic coefficients for three distinct velocity ranges, 0.220 above 2200 f.p.s., 0250 between 2200 and 1600 f.p.s., and 0.280 below 1600 f.p.s.. The estimation of 0.237 falls well within that range and would serve well as an average ballistic coefficient for the bullet.

![]()

![]()

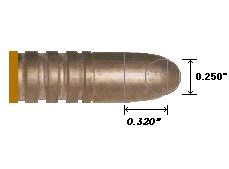

When a Cast bullet with slightly tapered round nose is encountered, measure the distance from the start of the nose curve, or radius, to the point where the tip begins, as illustrated below, and enter that value as Nose Length.

Note that the tip usually resembles a hemisphere or round ball before the curve changes to a radius curve as the illustration shows. Measure the diameter of this hemisphere where it joins the radius curve, as shown, and enter this value as the Tip Dia. Estimation of the ballistic coefficient of these large cast bullets is not as accurate as with the jacketed bullets, but the calculations do give a comparable estimate of a G1 ballistic coefficient

![]()

Copyright © 2002- 2010. TMT Enterprises. All rights reserved.